DC FANS DELIVER DESIGN FLEXIBILITY IN PORTABLE OXYGEN CONCENTRATORS

Individuals with lower blood oxygen concentration often require an oxygen concentrator to make breathing easier. Oxygen therapy is used to normalize the blood oxygen level during sleep, rest and activity. According to the American Thoracic Society (ATS), more than 1.5 million adults in the United States use supplemental oxygen to combat a variety of respiratory disorders. For most users, oxygen concentrators help improve their quality of life and increase their lifespan.

Early-model oxygen concentrators, however, were heavy and bulky, tethering patients to home or hospital, greatly impacting their ability to work, travel, or socialize. Newer models have incorporated more advanced (and smaller) components, so today’s portable oxygen concentrators (POCs) are smaller, lighter, and quieter than previous versions. They are easily transported and increase mobility for users, but their smaller footprints inherently increase the device’s heat density, increasing thermal load.

High-performance fans are required to cool temperature-sensitive components and efficiently remove waste heat. To meet modern POC design objectives, these fans must combine a compact design with high airflow and low noise operation.

BACKGROUND

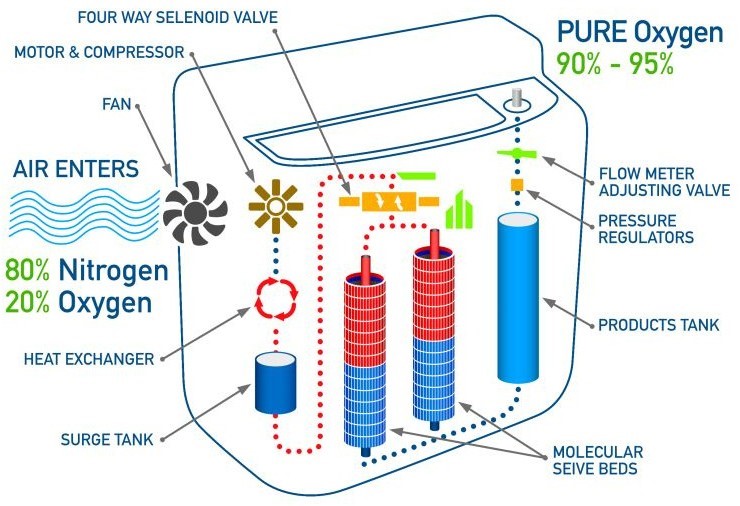

Oxygen concentrators operate in a manner similar to an air conditioning unit, but rather than compressing and conditioning the air to cool a building or vehicle, oxygen concentrators compress, condition, and purify the air to assist breathing. A POC intakes air through a motor, compresses that air, and moves it through two sieve beds and filters removing dust, pollen, pet hair, mites, and many other air contaminants that complicate breathing.

This is where the pressure drops, and nitrogen is released. The ambient air is collected at a ration around 20% oxygen and 80% nitrogen. After the compression and filtering process, the air is 90 to 95% oxygen. The purified, oxygen-rich air is then delivered to the patient via a nasal cannula or mask.

Portable oxygen concentrators can be powered by battery, electricity, or DC power. Weighing between 3 and 18 pounds, many can be carried in backpacks or pulled in carts. All POCs provide on-demand (pulse) flow oxygen delivery, and advanced models monitor the purity of the oxygen, allowing users to adjust delivery settings, flow rate and more.

DESIGN CHALLENGES

POCs should maintain their internal temperature no matter the external environment to which they are subjected. The equipment often is used outdoors, and experiences fluctuations in temperature and humidity. Weather and extreme temperatures can impact significantly the equipment’s performance. If the battery exceeds the temperature limit, its charge could diminish quickly. In some cases, the overheated battery could cause the unit to power down completely, a dangerous situation for the user if they are not close to home. Even if the battery continues to power the POC, the oxygen concentrator will not produce oxygen when the temperature crosses the tolerance range. For most oxygen concentrators, the operating temperature threshold is 104°F (40°C).

Additionally, the equipment’s components also play a role in maintaining the unit’s operating temperature. Smaller, more compact POCs feature densely packed components. Crowding more electronics into a smaller footprint increases the heat flux density. As a result, cooling solutions with higher airflows are required to move heat away from temperature-sensitive electronics. Airflows of 40 CFM are required in most POC designs to adequately provide proper cooling. In addition, the cooling solution must offer low power operation to ensure it does not add to the thermal load as well.

The noise generated by the unit should also be considered. Low-noise POCs, whether used in hospitals, in the home or on the go, are preferable for most users, who often don’t wish to draw attention to the machine or cause a distraction for others. In addition, a loud POC can interfere with everyday activities like watching TV, reading a book, conversing with others, or sleeping. POCs require fans that operate under 40 decibels to ensure everyone’s comfort.

POCs also must withstand the wear and tear of daily use. Portability requires ruggedization, and all electronics in a POC must be able to handle shock and vibration from normal daily mobile use. Most POCs are not waterproof, but resistance to moisture and humidity are critical characteristics of the cooling solutions chosen for their design.

DESIGN IN THE RIGHT COOLING SOLUTION

To meet these application demands while ensuring temperature-sensitive electronics remain cool, POCs often employ small DC fans. DC fans offer rugged and reliable operation with airflows well above 40 CFM and noise levels under 40 decibels — all at only 12V operation.

But not all DC fans are created equal. Fan manufacturers like Orion Fans sell and design advanced cooling solutions and value-added services for customers with unique problems. For example, Orion Fans recently developed a dual DC fan design for a POC manufacturer with a size constraint issue. The manufacturer was seeking a high-functioning miniature DC fan with a low height of under 20mm but was unable to find an off-the-shelf product from standard fan resellers and manufacturers. Orion Fans created a fan kit using two OD5015 Series DC fans assembled side by side.

At only 50mm x 50mm x 15mm, the OD5015 DC fans met the desired height clearance, and easily fit into the POC to cool electronics to ambient temperatures. Orion Fans assembled the fan kits using adhesive foam tape, leaving adequate spacing for vibration resistance and airflow.

In addition, Orion Fans also assembled two custom twisted leads with connectors. The wire leads are secured to stay in place, ensuring a proper connection for long-term operation. This value-added service lowered the POC manufacturer’s costs as well as reduced assembly time.

CONCLUSION

In addition, Orion Fans also assembled two custom twisted leads with connectors. The wire leads are secured to stay in place, ensuring a proper connection for long-term operation. This value-added service lowered the POC manufacturer’s costs as well as reduced assembly time.

Oxygen concentrators offer respiratory therapy by delivering necessary purified oxygen to users, and lightweight portable versions allow greater mobility for everyday activities and freedom to travel. As POC manufacturers continue to design smaller, lighter and quieter versions to meet this user demand, they will need to specify components, particularly for cooling solutions, that can address heat flux density. POC equipment’s footprint can vary significantly from one manufacturer to the next, and it will be increasingly difficult to find off-the-shelf fans and other cooling solutions that meet the system’s needs. Finding a fan manufacturer who offers design engineering and value-added services is an affordable, even cost-saving measure that will offer maximum flexibility in end-product design and end- user satisfaction.